Highly acclaimed Manufacturer & Exporter presents best offer ever on Slip-on Flanges

We can supply customized Slip-on Flanges per customers’ specifications, we welcome small quantity order.

Slip-on Flanges

Contents

1 Slip-on Flanges Specification

2 Slip-on Flanges Dimensions

3 Slip-on Flanges Godown

4 Slip-on Flanges Marking & Packaging

5 Slip-on Flanges Shipping Policy

6 Why choose us for Slip-on Flanges

7 Best Offer ever on Slip-on Flanges

8 Slip-on Flanges Price (at Factory Price)

9 Slip-on Flanges Uses & Application

MD Expots LLP is Manufacturer, Stockists & Supplier of premium quality range of Slip-on Flanges, Stainless Steel Flanges & Other Stainless Steel Pipe fittings that are manufactured under the expert guidance of our diligent workforce. we are highly experienced company in Slip-on Flanges & other pipe fittings. our Slip-on Flanges & Other Fitting products are manufactured using quality material and go through a rigorous quality check at all stages of production to ensure quality. Designed in compliance with international quality standards, these Slip-on Flanges are corrosion resistance, sturdy and durable. we also supply Slip-on Flanges & other pipe fittings Flanges in customized size. Our Product Supply Division offers a broad portfolio of Steel Flanges and Slip-on Flanges.

Quality assurance is carried throughout the process from the raw material purchasing to processing, packing, storage and transportation. Every process strictly conforms to the ISO 9001:2008. "Quality First" is our promise forever to any of our customers. Our Slip-on Flanges are 100% inspected before being packed and dispatched & all our materials are tested to International standards. We have 3 levels to check quality of Slip-on Flanges. We also accept any Third Party of Inspection appointed by our customers, such as Lloyd’s Register, TUV, DNV, BV, SGS, IEI, SAI and etc.

Slip-on Flanges / SORF Flange

The flange is slipped over the pipe and then welded both inside and outside to provide sufficient Strength and prevent leakage. This flange is used in preference to weld necks by many users because of its lower cost and the fact that less accuracy is required when cutting pipe to length.

Sizes for Slip On Flanges

All Slip On Flanges are available available in sizes from 1/4” through to any size.

Wall Thickness for Slip On Flanges

Schedule 5s through to Schedule XXS and heavier.

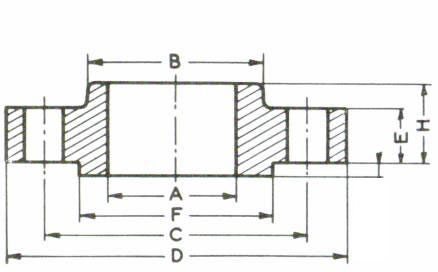

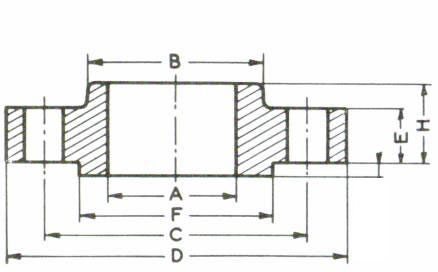

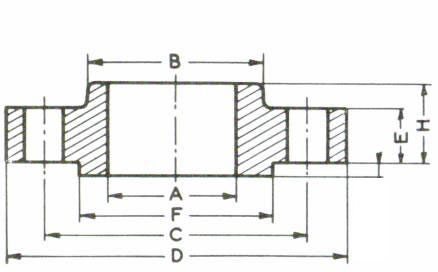

Dimensions

Diameter : 1/2" à 24"

Pressure class : 150# – 300# – 600# – 1500#

Dimensions and Pressure Ratings for Slip On Flanges:

- ANSI, MSS- SP-44, BS3293, API 605 150lb through to 2500lb

- Flange Facings: Raised Face, Ring Type Joint, Large Tongue & Groove, Small Tongue & Groove

– BS4504 – PN6, 10, 16, 25, 64

– BS10 – Table D, E, F, & H

– DIN Standards

Variations

Face finish : Raised face (RF) – Flat face (FF) – RTJ

Variations : Reducing Slip On – Orifice Slip On

Standards

ASTM A182 – ASME SA182 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’

ASME B16.5- ‘Pipe Flanges and Flanged Fittings’

ASME B16.36 -‘Orifice Flanges’

ASME B16.47 – ‘Large Diameter Steel Flanges NPS26 Through NPS60′

MSS SP-6 – ‘Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings’

150Lbs - 300Lbs - 600Lbs

The tables below show the most common sizes but are not exhaustive.

150 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 90 | 9.6 | 35.05 | 30 | 22.2 | 14 | 4 | 15.87 | 60.3 |

| 3/4" | 100 | 11.2 | 42.93 | 38 | 27.7 | 14 | 4 | 15.87 | 69.9 |

| 1" | 110 | 12.7 | 50.80 | 49 | 34.5 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4" | 115 | 14.3 | 63.50 | 59 | 43.2 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2" | 125 | 15.9 | 73.15 | 65 | 49.5 | 21 | 4 | 15.87 | 98.4 |

| 2" | 150 | 17.5 | 91.95 | 78 | 61.9 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2" | 180 | 20.7 | 104.65 | 90 | 74.6 | 27 | 4 | 19.05 | 139.7 |

| 3" | 190 | 22.3 | 127.00 | 108 | 90.7 | 29 | 4 | 19.05 | 152.4 |

| 3 1/2" | 215 | 22.3 | 139.70 | 122 | 103.4 | 30 | 8 | 19.05 | 177.8 |

| 4" | 230 | 22.3 | 157.22 | 135 | 116.1 | 32 | 8 | 19.05 | 190.5 |

| 5" | 255 | 22.3 | 185.67 | 164 | 143.8 | 35 | 8 | 22.22 | 215.9 |

| 6" | 280 | 23.9 | 215.90 | 192 | 170.7 | 38 | 8 | 22.22 | 241.3 |

| 8" | 345 | 27.0 | 269.75 | 246 | 221.5 | 43 | 8 | 22.22 | 298.5 |

| 10" | 405 | 28.6 | 323.85 | 305 | 276.2 | 48 | 12 | 25.40 | 362.0 |

| 12" | 485 | 30.2 | 381.00 | 365 | 327.0 | 54 | 12 | 25.40 | 431.8 |

| 14" | 535 | 33.4 | 412.75 | 400 | 359.2 | 56 | 12 | 28.57 | 476.3 |

| 16" | 595 | 35.0 | 469.90 | 457 | 410.5 | 62 | 16 | 28.57 | 539.8 |

| 18" | 635 | 38.1 | 533.40 | 505 | 461.8 | 67 | 16 | 31.75 | 577.9 |

| 20" | 700 | 41.3 | 584.20 | 559 | 513.1 | 71 | 20 | 31.75 | 635.0 |

| 24" | 815 | 46.1 | 692.15 | 663 | 616.0 | 81 | 20 | 34.92 | 749.3 |

1,6mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 – 2007

300 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 21.3 | 12.7 | 35.05 | 38 | 22.2 | 21 | 4 | 15.87 | 66.7 |

| 3/4" | 26.7 | 14.3 | 42.93 | 48 | 27.7 | 24 | 4 | 19.05 | 82.6 |

| 1" | 33.4 | 15.9 | 50.80 | 54 | 34.5 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4" | 42.2 | 17.5 | 63.50 | 64 | 43.2 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2" | 48.3 | 19.1 | 73.15 | 70 | 49.5 | 29 | 4 | 22.22 | 114.3 |

| 2" | 60.3 | 20.7 | 91.95 | 84 | 61.9 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2" | 73.0 | 23.9 | 104.65 | 100 | 74.6 | 37 | 8 | 22.22 | 149.2 |

| 3" | 88.9 | 27.0 | 127.00 | 117 | 90.7 | 41 | 8 | 22.22 | 168.3 |

| 3 1/2" | 101.6 | 28.6 | 139.70 | 133 | 103.4 | 43 | 8 | 22.22 | 184.2 |

| 4" | 114.3 | 30.2 | 157.22 | 146 | 116.1 | 46 | 8 | 22.22 | 200.0 |

| 5" | 141.3 | 33.4 | 185.67 | 178 | 143.8 | 49 | 8 | 22.22 | 235.0 |

| 6" | 168.3 | 35.0 | 215.90 | 206 | 170.7 | 51 | 12 | 22.22 | 269.9 |

| 8" | 219.1 | 39.7 | 269.75 | 260 | 221.5 | 60 | 12 | 25.40 | 330.2 |

| 10" | 273.0 | 46.1 | 323.85 | 321 | 276.2 | 65 | 16 | 28.57 | 387.4 |

| 12" | 323.8 | 49.3 | 381.00 | 375 | 327.0 | 71 | 16 | 31.75 | 450.8 |

| 14" | 355.6 | 52.4 | 412.75 | 425 | 359.2 | 75 | 20 | 31.75 | 514.4 |

| 16" | 406.4 | 55.6 | 469.90 | 483 | 410.5 | 81 | 20 | 34.92 | 571.5 |

| 18" | 457.0 | 58.8 | 533.40 | 533 | 461.8 | 87 | 24 | 34.92 | 628.6 |

| 20" | 508.0 | 62.0 | 584.2td> | 587 | 513.1 | 94 | 24 | 34.92 | 685.8 |

| 24" | 610.0 | 68.3 | 692.15 | 702 | 616.0 | 105 | 24 | 41.27 | 812.8 |

1,6mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 – 2007

600 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 21.3 | 14.3 | 35.05 | 38 | 22.2 | 22 | 4 | 15.87 | 66.7 |

| 3/4" | 26.7 | 15.9 | 42.93 | 48 | 27.7 | 25 | 4 | 19.05 | 82.6 |

| 1" | 33.4 | 17.5 | 50.80 | 54 | 34.5 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4" | 42.2 | 20.7 | 63.50 | 64 | 43.2 | 29 | 4 | 19.05 | 98.4 |

| 1 1/2" | 48.3 | 22.3 | 73.15 | 70 | 49.5 | 32 | 4 | 22.22 | 114.3 |

| 2" | 60.3 | 25.4 | 91.95 | 84 | 61.9 | 37 | 8 | 19.05 | 127.0 |

| 2 1/2" | 73.0 | 28.6 | 104.65 | 100 | 74.6 | 41 | 8 | 22.22 | 149.2 |

| 3" | 88.9 | 31.8 | 127.00 | 117 | 90.7 | 46 | 8 | 22.22 | 168.3 |

| 3 1/2" | 101.6 | 35.0 | 139.70 | 133 | 103.4 | 49 | 8 | 25.40 | 184.2 |

| 4" | 114.3 | 38.1 | 157.22 | 152 | 116.1 | 54 | 8 | 25.40 | 215.9 |

| 5" | 141.3 | 44.5 | 185.67 | 189 | 143.8 | 60 | 8 | 28.57 | 266.7 |

| 6" | 168.3 | 47.7 | 215.90 | 222 | 170.7 | 67 | 12 | 28.57 | 292.1 |

| 8" | 219.1 | 55.6 | 269.75 | 273 | 221.5 | 76 | 12 | 31.75 | 349.2 |

| 10" | 273.0 | 63.5 | 325.85 | 343 | 276.2 | 86 | 16 | 34.92 | 431.8 |

| 12" | 323.8 | 66.7 | 381.00 | 400 | 327.0 | 92 | 20 | 34.92 | 489.0 |

| 14" | 355.6 | 69.9 | 412.75 | 432 | 359.2 | 94 | 20 | 38.10 | 527.0 |

| 16" | 406.4 | 76.2 | 469.90 | 495 | 410.5 | 106 | 20 | 41.27 | 603.2 |

| 18" | 457.0 | 82.6 | 533.40 | 546 | 461.8 | 117 | 20 | 44.45 | 654.0 |

| 20" | 508.0 | 88.9 | 584.20 | 610 | 513.1 | 127 | 24 | 44.45 | 723.9 |

| 24" | 610.0 | 101.6 | 692.15 | 718 | 616.0 | 140 | 24 | 50.80 | 838.2 |

6,4 raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 – 2007

Slip-on Flanges Godown

we are the manufacturer of Slip-on Flanges, we have our own A 3 level 10,000 feet and well equipped warehouse located at Kalamboli, Navi Mumbai, India. We thanks to our skilled staff, we can produce a large number of Slip-on Flanges that comply with the different current standards. Choosing and selecting our raw materials is one of the keys to our production.

we are the manufacturer of Slip-on Flanges, we have our own A 3 level 10,000 feet and well equipped warehouse located at Kalamboli, Navi Mumbai, India. We thanks to our skilled staff, we can produce a large number of Slip-on Flanges that comply with the different current standards. Choosing and selecting our raw materials is one of the keys to our production.

Slip-on Flanges Marking & Packaging

Slip-on Flanges Marking

Slip-on Flanges Packaging

While marking we choose a specific item number as well different color shade to differentiate steel grades. We mark Slip-on Flanges as needed with the most suitable & visible marking technique.

Our experienced warehouse guys are always ready to pick out your order and get it ready for delivery. we package and pack the Slip-on Flanges according to customers’ specification & as per the appropriate method such as wooden crate, strapped pallet, overseas packing (ISPM15). Do you know Hardened containers (plywood, metal) that are not banded should have an exterior lock or clamp. (Glue, nails and screws are not sufficient.) We know proper packaging of your freight is the best way to ensure that your goods arrive safely at their destination.

Shipping Policy

Delivery time and delivery dates are based on the "type and quantity" of steel ordered. Our sales team will provide a delivery schedule when quoting to you. On rare occasions the delivery schedule may change so please check with our sales department when placing any orders.

Orders will be sent out within 2-3 business days, and may take up to 5-10 business days in transit. If Slip-on Flanges is out of stock, orders may take up to 2-4 weeks to ship. MD Expots LLP will notify buyer if this situation occurs.

Why choose us for Slip-on Flanges?

1. On-Time Delivery Every Time

2. Competitive Prices

3. High Quality Product

4. Quick Response by Email & by Phone

5. An ISO 9001:2008 Certified Company

Third Party Inspection

We offer to our clients the third party inspection of Slip-on Flanges from reputed agencies such as LLOYDS, EIL, H&G, TCE, PDIL, MECONS, M.N. DASTUR & Co., Bax council, DNV, Bureau Veritas, DPG, SGS, IRS, and many others.

We offer to our clients the third party inspection of Slip-on Flanges from reputed agencies such as LLOYDS, EIL, H&G, TCE, PDIL, MECONS, M.N. DASTUR & Co., Bax council, DNV, Bureau Veritas, DPG, SGS, IRS, and many others.

| THIRD PARTY INSPECTION AGENCIES SERVICES UNDER OUR SCOPE | |

| Tecnimont ICB Limited | ICB |

| DET Norske Veritas | DNV |

| Fact Engineering And Design Organisation | FEDO |

| Projects & Developments India Limited | PDIL |

| Baxcounsel Inspection Bureau Pvt. Ltd. | Baxcounsel |

| Bureau Veritas Industrial Services (India) Pvt. Ltd. | BVIS |

| Industrial Consultancy And Inspection Services | ICIS |

| Metallurgical & Engineering Consultants (India) Ltd. | MECON |

| Nuclear Power Corporation Of India Ltd. | NPCL |

| Engineers India Limited | EIL |

| Bharat Heavy Electricals Limited | BHEL |

| UHDE India Limited | UHDE |

| Pipecon Consultants (India) Pvt. Ltd. | PIPECON |

| Indian Boiler Regulations | IBR |

Best Offer ever on Slip-on Flanges

We have our own warehouse of 10,000 feet, so we can offer best price in the market. Optimized financial concepts can be offered on request as well.

Slip-on Flanges Application

MD Expots LLP take immensure pleasure in introducing itself as one of the leading Manufacturer & Exporter of high quality Slip-on Flanges to meet the customer ultimate requirements in the fields of:

- Chemical

- Petrochemical

- Refineries

- Fertilizers

- Power Plant

- Nuclear Power

- Oil & Gas

- Paper

- Breweries

- Cement

- Sugar

- Oil Mills

- Mining

- Construction

- Shipbuilding

- Steel Plant

- Offshore

- Defence

- Ports

- Railway

- Engineering Co. &

- Government Org. etc.

Slip-on Flanges Price

Check below aproximate price for our customers who are intrested to buy Slip-on Flanges

We’ve been manufacturing Slip-on Flanges since 2002. Our operations are ISO 9001:2008 certified, and we can deliver a 20-foot container order in 3-4 weeks. Browse through our Product Showroom, and then send us your inquiries. Here, we always reply within 24 hours.

Competitive Advantages

- OEM Capability

- Large Product Line

- Reliability

- Reputation

- Buyer’s Specifications Accepted

- Prompt delivery

Main Export Market

- Eastern Europe

- North America

- Mid East/Africa

- Central/South America

- Asia

- Western Europe

- Australasia

- UAE

Sales Locations

U.A.E, Oman, Saudi Arabia, Qatar, Bahrain, Egypt, Turkey, Singapore, Thailand, Malaysia, Indonesia, Poland, Italy, Portugal, Spain, Brazil, Chile, Venezuela, Costa Rica, USA, Canada, Angola, Sri Lanka, Russia

Global market we export to:

In order to provide quality Slip-on Flanges to our clients of the nation we have taken the initiative to import so as to supply them materials of world’s best mills and corporations. This has helped us to strive for establishing ourselves firmly in all our market segments.